As manufacturers embrace Industry 4.0, digital twin technology and the Internet of Things (IoT) are creating smarter, more efficient, and highly predictive manufacturing environments. But how does digital twin in IoT function, and why is this integration so powerful?

By combining real-time sensor data from IoT devices with the virtual modeling capabilities of digital twins, manufacturers can monitor, analyse, and optimise physical assets and processes like never before. This improves quality control and predictive maintenance and enhances operational efficiency across industries like automotive, aerospace, rail and marine manufacturing.

What is a Digital Twin in IoT?

A digital twin is a real-time virtual replica of a physical asset, system, or process, continuously updated using data from sensors, IoT devices, and machine learning algorithms. Unlike traditional models or static simulations, digital twins evolve to reflect actual conditions as they change.

IoT in manufacturing refers to the network of connected sensors, machines, and devices that collect and transmit data across a system. When integrated with a digital twin, IoT devices provide a continuous stream of real-world data, enabling accurate modeling, predictive analytics, and intelligent decision-making.

How Digital Twin and IoT Work Together

The integration of digital twin in IoT works through a continuous feedback loop between the physical and digital worlds. Here’s how it functions:

1. IoT Collects Real-Time Data from Physical Assets

IoT sensors are embedded in machinery, vehicles, or production lines to continuously capture performance data such as:

- Temperature fluctuations

- Pressure levels

- Equipment vibrations

- Energy consumption

- Environmental conditions

This data is instantly transmitted to a digital twin, where it is analysed and compared to expected benchmarks.

2. Digital Twin Analyses and Predicts Performance

Once the real-world data is received, the digital twin processes and visualises it in a virtual environment. With AI and machine learning capabilities, digital twins can:

- Identify performance deviations.

- Detect early warning signs of failures.

- Simulate different scenarios to test potential optimisations.

- Predict when maintenance should occur to prevent breakdowns.

In manufacturing, this means a production manager can observe a machine’s digital twin and anticipate wear and tear before an actual failure disrupts operations.

3. IoT and Digital Twins Enable Smart Decision-Making

Instead of reacting to failures after they occur, manufacturers can use predictive insights from digital twins to make proactive decisions. This leads to:

- Reduced downtime: Fixing problems before they escalate.

- Optimised energy use: Adjusting machinery settings for efficiency.

- Enhanced product quality: Detecting defects earlier in production.

- Lower maintenance costs: Scheduling repairs only when necessary.

With FLAGS Software’s smart quality management solutions, manufacturers can leverage digital twin and IoT integration to maintain optimal efficiency and eliminate costly errors in production.

Real-World Applications of Digital Twin and IoT

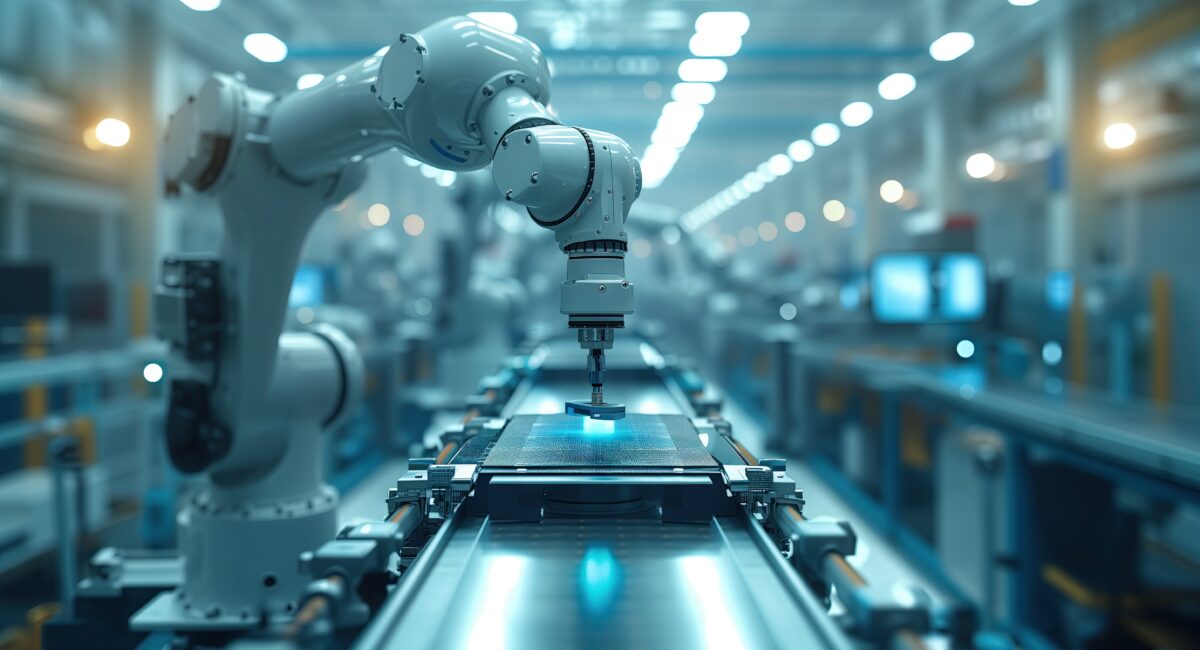

1. Smart Factories and Predictive Maintenance

In modern smart factories, IoT sensors continuously track machine performance, and digital twins use this data to simulate failures before they happen. Instead of waiting for a breakdown, manufacturers receive alerts when a part is wearing out, allowing maintenance to be scheduled at the perfect time.

2. Aerospace and Aircraft Optimisation

Aircraft manufacturers use digital twins to analyse engines, landing gear, and cabin systems in real time. IoT sensors track in-flight performance, sending live data to digital twins that can predict mechanical failures, suggest fuel efficiency optimisations, and improve overall safety.

3. Automotive Production and Fleet Management

In the automotive industry, digital twins paired with IoT provide manufacturers with real-time production insights. Every stage of vehicle assembly is monitored, ensuring quality control at each step.

Fleet managers also use digital twins to:

- Track vehicle wear and tear in real time.

- Improve fuel efficiency through IoT-powered optimisation.

- Reduce unexpected breakdowns with predictive maintenance alerts.

The Benefits of Combining Digital Twin and IoT

1. Improved Efficiency & Productivity

By monitoring machine performance in real time, manufacturers can eliminate inefficiencies and optimise production processes without stopping operations.

2. Reduced Costs & Waste

Predictive analytics minimise unnecessary maintenance and production waste, leading to significant cost savings. Manufacturers only use resources when and where they’re needed.

3. Enhanced Quality Control

Manufacturers can detect defects earlier in the production process, ensuring that only high-quality products reach customers. Digital twins allow for real-time error detection and correction before costly mistakes occur.

4. Greater Sustainability

By optimising resource usage and energy consumption, IoT-driven digital twins contribute to greener manufacturing practices, reducing carbon footprints and overall waste.

The Future of Digital Twin and IoT in Manufacturing

The integration of digital twin in IoT is paving the way for fully autonomous, self-optimising factories and supply chains. As AI, machine learning, and IoT technologies continue to evolve, manufacturers will gain even deeper insights into operations, unlocking unprecedented levels of efficiency, sustainability, and cost savings.

At FLAGS Software, we are committed to helping manufacturers leverage digital twin technology and IoT to achieve smarter, more efficient, and high-quality production.

Earlier this year, our Director of Operations, Richard Mott went to the Smart Manufacturing Expo and discussed how FLAGS helps build the full operational history of a vehicle – from bare metal to sold product – through digital twin technology.

Harness the Power of Digital Twin in IoT with FLAGS Software

Are you ready to integrate digital twin and IoT into your manufacturing processes? Discover how FLAGS Software can help you reduce downtime, improve quality control, and optimise production with real-time insights.

Contact us today to explore our cutting-edge solutions and take the next step toward smarter, data-driven manufacturing.