The Digital Twin is a cornerstone technology of Industry 4.0, seamlessly connecting physical industrial products with the digital world. At FLAGS Software, we use data with predictive modelling to harness extensive data analytics, empowering manufacturers by enhancing decision-making and operational efficiency throughout the lifecycle of their assets.

What is a Digital Twin?

A Digital Twin is (according to IDTA) a “digital representation, sufficient to meet the requirements of a set of use cases.” Contrary to popular belief, a Digital Twin isn’t a virtual image or replication of a component or product. It is a methodology that creates a data image of any component/part you want to analyse the performance of. The component or part is referred to as an asset.

Data is continuously gathered, monitored, and analysed to evaluate an asset’s real-time performance against its designed capabilities. Digital Twins enhance the manufacturing process by comparing expected outcomes with actual results. Professionals are realising the power that Digital Twin in manufacturing can provide for various industries including automotive, aerospace, and rail.

For example, in a manufacturing paint process where dirt in paint is being investigated, rising defect rates can adversely impact KPIs, making it crucial to identify the cause. Data scientists may utilise FLAGS data alongside simulation data to analyse process performance.

Digital Twin with FLAGS

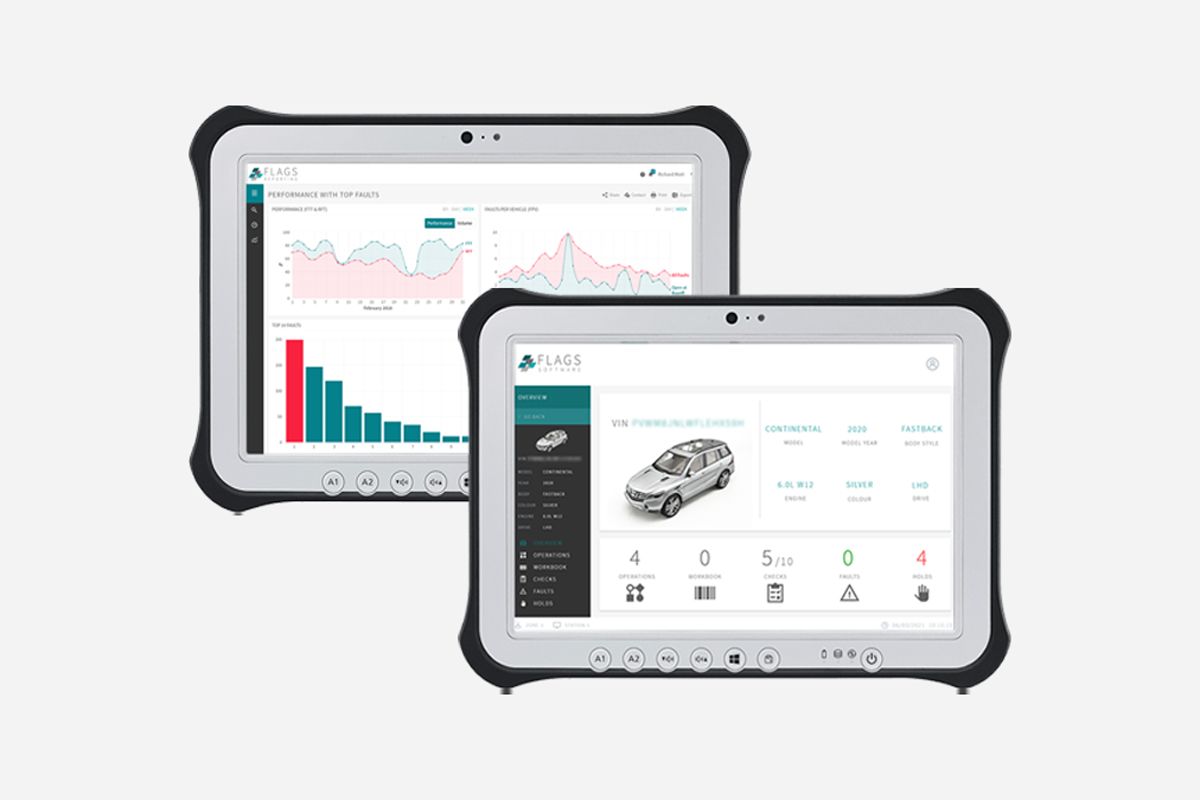

Utilising the IDTA’s AAS (Asset Administration Shell) framework, FLAGS is a key contributor to the Digital Twin, providing insight into each asset’s performance. Data scientists can use FLAGS quality data with predictive modelling to analyse complex problems and understand the impact of changes or disruptions. This is then fed back and design changes are made to the asset or the process itself.

OX Delivers partnership

Since 2022, we’ve partnered with OX Delivers and Coventry University on Project CLEAN (Clean Logistics for Emerging African Nations) to develop flat-pack, all-terrain electric trucks for emerging markets.

Through the use of Digital Twin, FLAGS Software is providing key insights and helping to address the manufacturing and maintenance of trucks. Initial use cases focused on tyre wear and brakes, analysing tread wear and interaction with various terrains to identify the impact these variables have on the truck’s performance. These first steps are quite simple representations, our goal is to extend this analysis to more complex scenarios, transitioning from theoretical models to practical, impactful solutions that will ensure the design and production of these trucks meets the required quality standards. Protecting the manufacturer’s brand image as well as delivering cost and time benefits. Find out more about the project.

The benefits of Digital Twin

From acting as a digital stamp of approval to validating products, implementing Digital Twin technology offers numerous advantages:

- Predictability and problem-solving: Foresee potential issues before they arise.

- Improving product design: Design iteration based on real-world data.

- Preventative maintenance: Address problems before they lead to failure or rework.

- Reduced downtime: Minimise interruptions by predicting when maintenance is needed.

- Continuous improvement: Constantly refine products based on the latest insights.

- Enhanced brand awareness: Brand visibility is amplified through innovative performance insights.

- Improved customer satisfaction: Delivering products that meet, and where possible, exceed expectations.

Take your first step to heightened quality, control and traceability today.

FLAGS Software is here to help enhance your production and manufacturing processes to achieve a new level of excellence. Our team of experts have decades of experience helping manufacturers unlock their potential and are waiting to help you do the same.