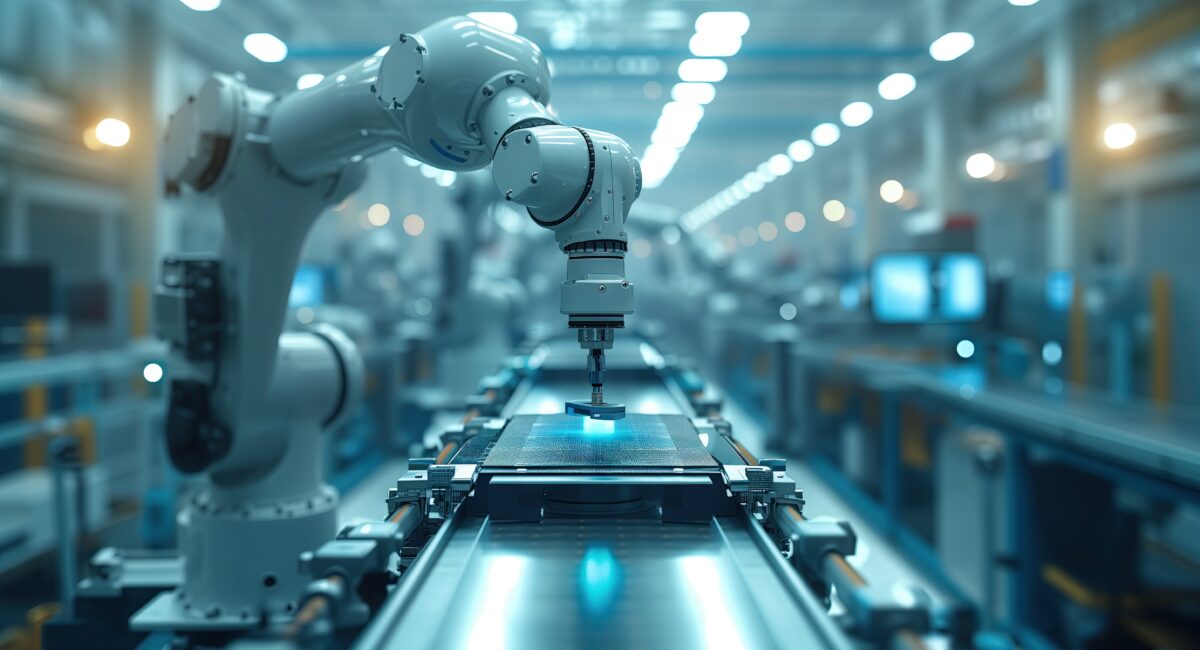

AI in data science is revolutionising industries worldwide. Especially when it comes to manufacturing. In a sector where precision, efficiency, and quality control are paramount, AI-powered data science is enabling manufacturers to make smarter decisions, reduce rework and optimise production like never before.

By leveraging machine learning algorithms, predictive analytics and automation, AI is enhancing manufacturing processes at every stage, from raw material sourcing to final product inspection.

The result? Increased efficiency, improved sustainability, and higher-quality output.

What is AI in Data Science?

AI in data science refers to the use of artificial intelligence to analyse vast amounts of structured and unstructured data, identifying patterns, making predictions, and automating decision-making. Traditionally, data analysis requires manual processing and interpretation, which is often slow and prone to human error. In comparison, AI can process complex datasets in real time, uncovering insights that would otherwise go unnoticed.

In manufacturing, this means AI can:

- Monitor production lines to detect inefficiencies.

- Analyse machine data to predict failures before they occur.

- Improve quality control by identifying defects with unparalleled accuracy.

- Enhance supply chain logistics by optimising resource allocation.

This integration of AI with data science allows manufacturers to transition from reactive problem-solving to proactive optimisation, ensuring a more efficient and cost-effective operation.

How is AI Used in Data Science to Improve Manufacturing?

Preventing Downtime Before It Happens

Equipment failure is a major challenge in manufacturing, often leading to unplanned downtime, costly repairs, and production delays. AI-driven predictive maintenance is transforming how manufacturers maintain machinery and prevent failures before they occur.

By continuously analysing real-time data from IoT sensors, AI can detect early warning signs of potential malfunctions. Rather than relying on scheduled maintenance, manufacturers can service equipment only when needed, reducing unnecessary costs and minimising disruptions.

At FLAGS Software, we integrate AI-driven predictive maintenance solutions to help manufacturers extend machine lifespan, optimise maintenance schedules, and reduce operational risks.

AI in Quality Control

Ensuring product quality has always been a priority in manufacturing, but traditional quality control methods are often time-consuming, subjective and leave room for error. AI-powered machine learning algorithms now enable manufacturers to inspect products with unmatched precision, identifying even the smallest defects that might escape the human eye.

Instead of manual inspections, AI can:

- Analyse thousands of product images per second.

- Detect inconsistencies in materials or components.

- Improve accuracy over time by learning from past defect patterns.

By integrating AI into FLAGS Software’s quality management systems, manufacturers in automotive, aerospace, rail and marine industries can achieve greater consistency, reduce waste and uphold stringent quality standards.

AI and Digital Twin Technology: Creating Smarter Factories

The combination of AI and digital twin technology plays a key part in the smart factory. A digital twin is a real-time virtual replica of a physical system, whether it’s a production line, an aircraft component, or an entire factory. AI enhances digital twins by simulating real-world conditions, allowing manufacturers to:

- Optimise production processes before making costly physical changes.

- Test new product designs in a risk-free virtual environment.

- Predict performance outcomes based on historical and real-time data.

For aerospace manufacturers, for example, a digital twin of an aircraft engine can continuously analyse temperature, pressure, and vibration data to detect anomalies, ensuring safety and reliability. At FLAGS Software, we work with manufacturers to integrate AI-powered digital twins for smarter, more efficient production strategies.

The Future of AI in Data Science for Manufacturing

As AI technology continues to evolve, its role in manufacturing data science will only grow stronger. From self-optimising production lines to fully automated smart factories, the possibilities are limitless. Companies that embrace AI-driven data science today will be industry leaders tomorrow, setting new standards in efficiency, sustainability, and quality control.

At FLAGS Software, we specialise in AI-powered quality management solutions, predictive maintenance and digital twin integration to help manufacturers transform their operations with intelligent, data-driven insights.

Unlock the Power of AI in Data Science with FLAGS Software

The future of manufacturing belongs to those who leverage AI to drive efficiency, sustainability, and innovation. If you’re ready to explore how AI-powered data science can optimise your production, reduce costs, and enhance product quality, we’re here to help.

Contact FLAGS Software today to take the next step toward a smarter, more data-driven future in manufacturing.