Sustainable manufacturing has become a necessity. As industries face increasing pressure to reduce their carbon footprint and operate more responsibly, technologies like artificial intelligence (AI) are leading the charge toward greener, more eco-friendly practices.

For manufacturers in automotive, aerospace, rail, and marine, adopting AI-driven solutions is not only beneficial for the planet but also for operational efficiency and long-term profitability.

What is sustainable manufacturing?

Sustainable manufacturing refers to the creation of products through processes that minimise environmental impact while conserving energy and natural resources. It’s about doing more with less—less waste, less energy, and fewer emissions—while maintaining or even improving product quality.

At FLAGS Software, we are committed to helping manufacturers adopt sustainable practices through innovative AI solutions that drive efficiency, reduce waste, and enhance sustainability.

The role of AI in sustainable manufacturing

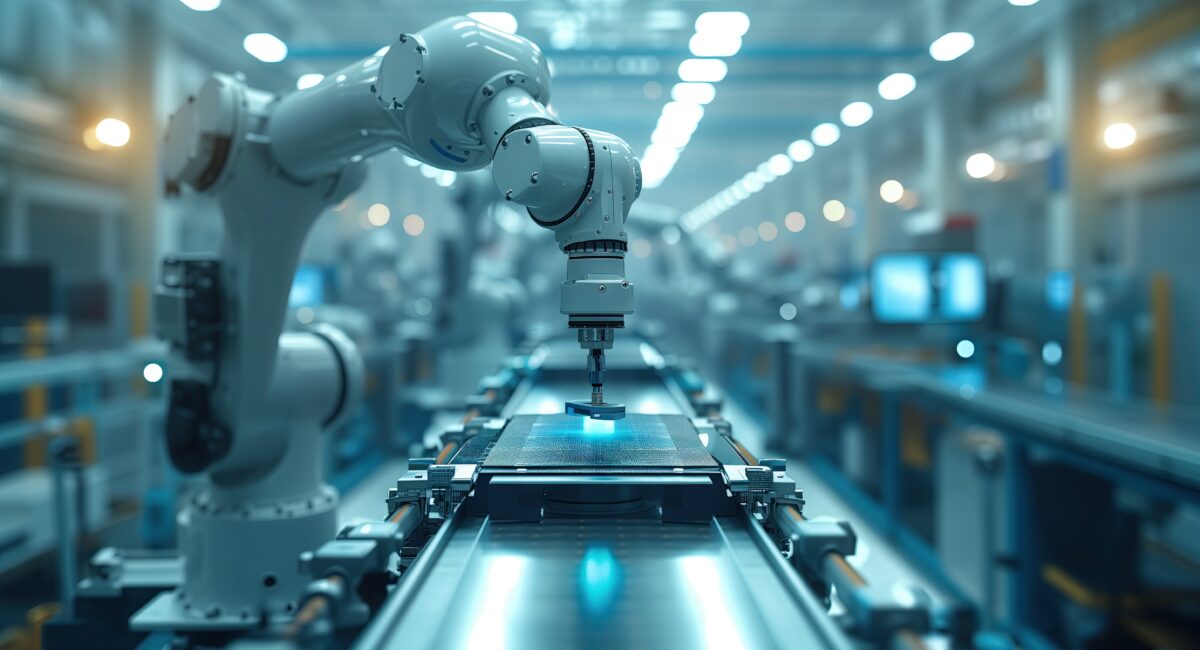

Artificial intelligence is revolutionising the manufacturing industry by enabling smarter, more efficient processes. Here’s how AI is contributing to green manufacturing:

1. Reducing waste and scrap

AI-powered quality control systems, like those offered by FLAGS Software, analyse production data in real time to detect defects and inefficiencies. This ensures that only high-quality products move forward in the production line, significantly reducing waste.

2. Optimising energy usage

AI systems can monitor and manage energy consumption across manufacturing plants, identifying areas where energy is wasted and optimising machine usage. This not only cuts costs but also lowers greenhouse gas emissions, aligning with green manufacturing goals.

3. Enabling predictive maintenance

Predictive maintenance, driven by AI, reduces unplanned downtime by identifying equipment issues before they lead to failures. By maintaining machinery at peak efficiency, manufacturers can avoid energy-intensive breakdowns and ensure sustainable operations.

4. Streamlining supply chains

AI enables better forecasting and inventory management, reducing excess stock and the environmental costs of overproduction and transportation. This results in a more sustainable and efficient supply chain.

5. Designing for sustainability

AI-powered simulations and digital twin technologies allow manufacturers to test and refine eco-friendly product designs before physical production. This minimises the need for resource-heavy prototyping, reducing material waste and energy usage.

AI in Action with FLAGS Software

At FLAGS Software, we empower manufacturers to adopt sustainable manufacturing practices through AI-driven quality management solutions. Our tools integrate seamlessly with IoT and digital twin technologies, providing real-time insights into production processes.

For instance, our partnership with OX Delivers demonstrates the power of AI in reducing waste and optimising design. By using AI to analyse tyre wear and brake performance in all-terrain electric trucks, we’re helping create sustainable solutions for emerging markets while minimising resource consumption during development.

The benefits of green manufacturing with AI

Adopting AI in manufacturing doesn’t just benefit the environment—it offers tangible advantages for businesses:

- Cost savings: Reduced energy consumption and waste translate to lower operational costs.

- Enhanced efficiency: AI-driven automation and monitoring improve overall productivity.

- Regulatory compliance: Meeting sustainability standards helps manufacturers avoid penalties and maintain brand reputation.

- Competitive advantage: Eco-friendly practices are increasingly valued by customers and stakeholders, giving manufacturers an edge in the market.

The future of manufacturing is green

As industries embrace Industry 4.0, AI will play an even greater role in driving sustainable manufacturing practices. By integrating AI-powered tools, manufacturers can reduce their environmental impact while enhancing efficiency and profitability.

At FLAGS Software, we’re committed to leading this transformation. Our smart quality management solutions are designed to help manufacturers achieve their sustainability goals without compromising on quality or performance.

Ready to embrace the future of green manufacturing? Discover how FLAGS Software can help your business leverage AI to optimise processes, reduce waste, and build a more sustainable operation. Contact us today to learn more about our solutions.