As the aerospace industry strives for greater precision, safety, and efficiency; digital twin technology plays a key role in this. From aircraft design to airport operations, digital twinning is transforming how engineers and manufacturers approach quality control, maintenance, and operational excellence.

What is a Digital Twin in Aerospace?

A digital twin is a virtual representation of a physical object, system, or process. It is constantly updated with real-time data from sensors and IoT devices. In aerospace, digital twins are used to replicate and monitor everything from aircraft systems to airport infrastructure, creating a dynamic connection between the physical and digital worlds.

Unlike traditional simulations, a digital twin evolves alongside their physical counterparts, enabling engineers and manufacturers to:

- Predict and prevent potential failures.

- Optimise performance.

- Improve decision-making with actionable insights.

Applications of Digital Twin Technology in Aerospace

1. Aircraft Digital Twins: Enhancing Design and Maintenance

Aircraft digital twins provide real-time data on performance, wear and tear, and system functionality. This enables aerospace engineers to:

- Enhance design: A digital twin allows engineers to test design changes in a virtual environment, ensuring optimal performance before implementation.

- Predictive maintenance: By monitoring real-time data, digital twinning can predict when maintenance is needed, reducing downtime and extending the lifespan of components.

- Quality control: Manufacturers can use digital twins to detect production inconsistencies and ensure all aircraft meet stringent safety and quality standards.

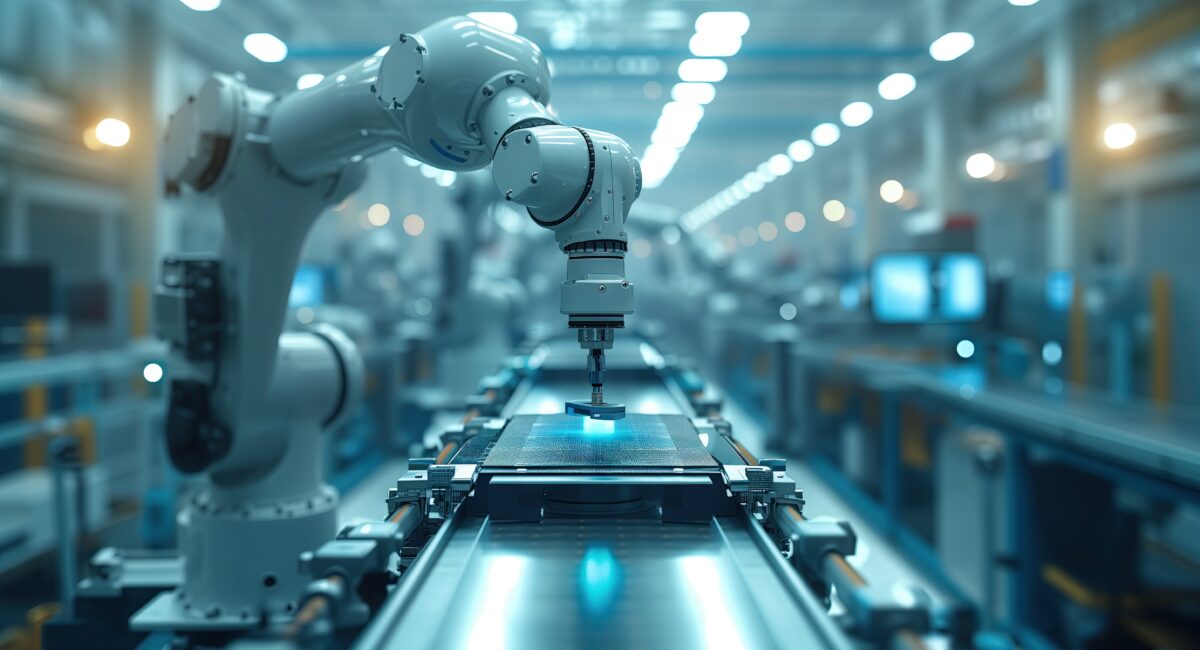

2. Aerospace Digital Twins: Improving Manufacturing Processes

In manufacturing, digital twins are used to model and monitor production lines, enabling:

- Process Optimisation: A digital twin analyses workflows to identify inefficiencies, ensuring precision and reducing waste.

- Traceability: By integrating with quality management systems like FLAGS Software, digital twins provide end-to-end visibility of production, ensuring compliance with aerospace regulations.

- Continuous improvement: Real-time data enables manufacturers to refine processes and improve product quality iteratively.

3. Airport Digital Twins: Enhancing Operations and Sustainability

Digital twins are not limited to aircraft—they are also revolutionising airport operations. Key benefits include:

- Operational Efficiency: By simulating passenger flow, digital twins help optimise airport layouts, reduce bottlenecks, and improve the overall passenger experience.

- Sustainability: A digital twin enables airports to monitor energy usage, minimise resource waste, and achieve greener operations.

- Collaboration: Airport digital twins provide a shared virtual environment for stakeholders to analyse and improve operations collaboratively.

The Synergy of Digital Twins in Aerospace Quality Control

The true power of digital twins in aerospace lies in their ability to create a seamless synergy between design, production, and operation. For quality control, this means:

- Real-Time Insights: Digital twins provide continuous updates, allowing engineers to identify and resolve quality issues as they arise.

- Data-Driven Decisions: By analysing historical and real-time data, manufacturers can make informed decisions to optimise quality and performance.

- Predictive Analytics: Anticipate and prevent defects or failures before they occur, reducing rework and ensuring compliance with industry standards.

At FLAGS Software, we specialise in integrating digital twin technology with quality management systems, helping aerospace manufacturers achieve unparalleled precision and reliability.

The Future of Digital Twins in Aerospace

As the aerospace industry continues to embrace innovation, digital twin technology will play an increasingly vital role in shaping the future of aircraft manufacturing and airport operations. By bridging the gap between physical and digital, aerospace digital twins empower manufacturers and engineers to deliver safer, more efficient, and environmentally conscious solutions.

Partner with FLAGS Software for Aerospace Digital Twin Solutions

At FLAGS Software, we are at the forefront of digital twin innovation, providing innovative solutions tailored to the unique needs of aerospace manufacturers and engineers. From optimising production lines to enhancing aircraft and airport operations, our technology drives excellence in quality control.

Take the first step toward smarter, more sustainable aerospace manufacturing. Contact us today to learn how FLAGS Software can revolutionise your approach to quality control with digital twin technology.